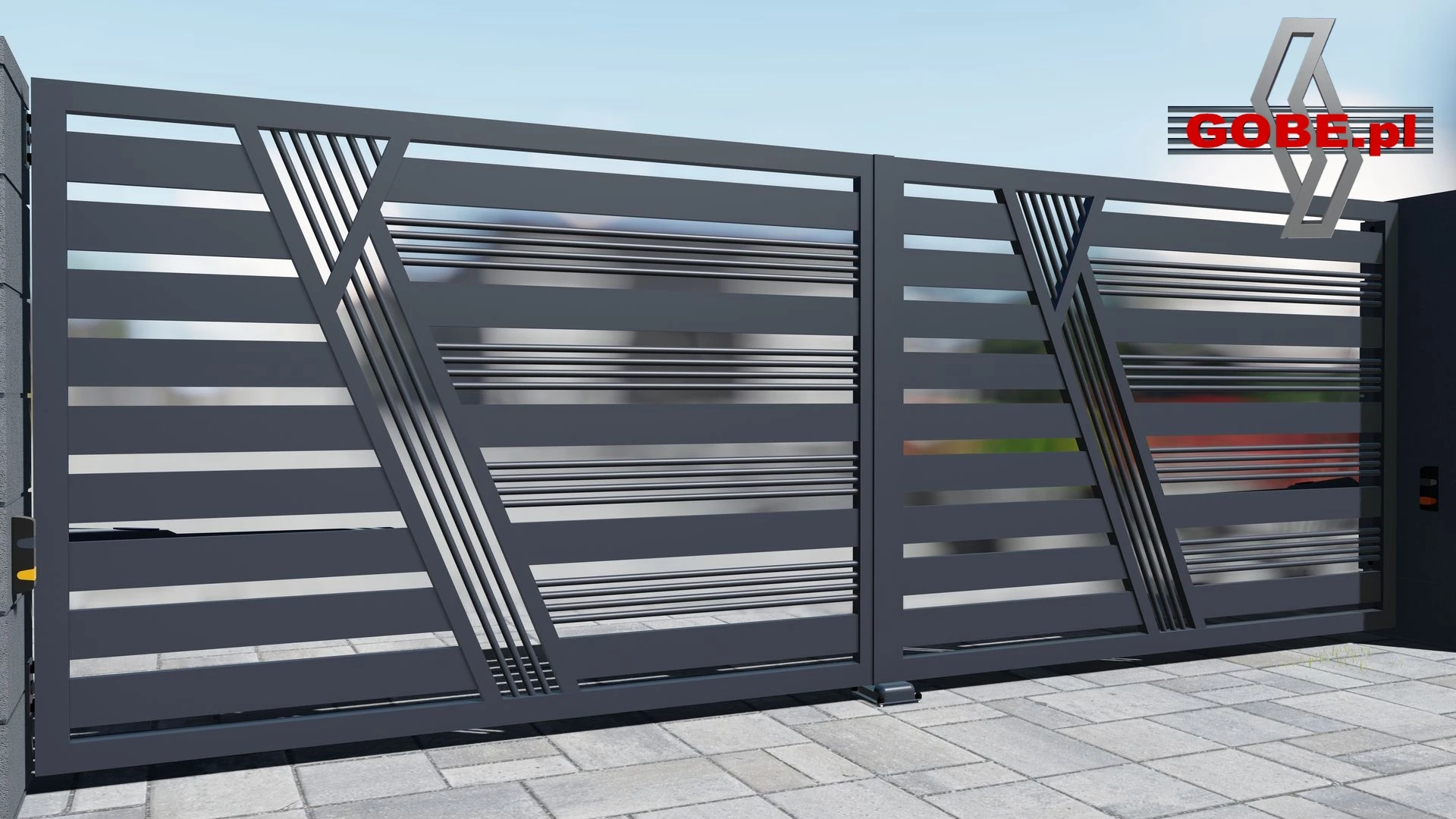

Cool entry fences fence gates model Galaxy 374

Modern fencing system

Inspirations concept

Standard i na wymiar

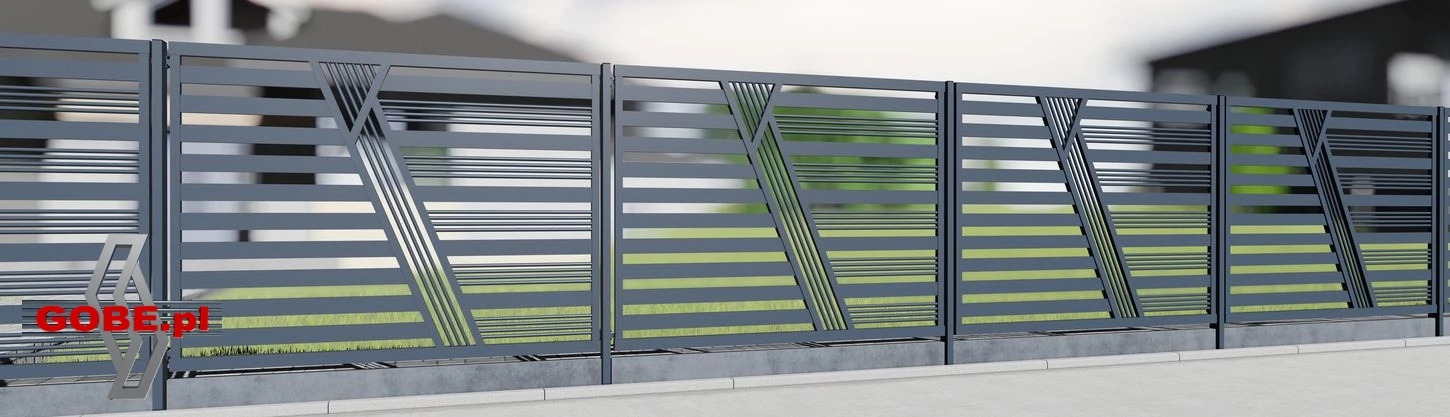

On the market, the offer of modular fence systems is very rich, currently the most popular concrete block systems are all forms of smooth surface. A springboard from split concrete block systems it may be dictated by a change or the next stage in the development of modern architecture, manor houses and wrought iron fences have years of splendor behind them. We will present the inspiration for using the 374 model in several forms of fencing, equally in the form of filling for modular blocks and forms of a metal fence. offer for several standard dimensions for such a system. Blocks can have different sizes for this is also the option of manufacturing fence elements to size.

Customized designs

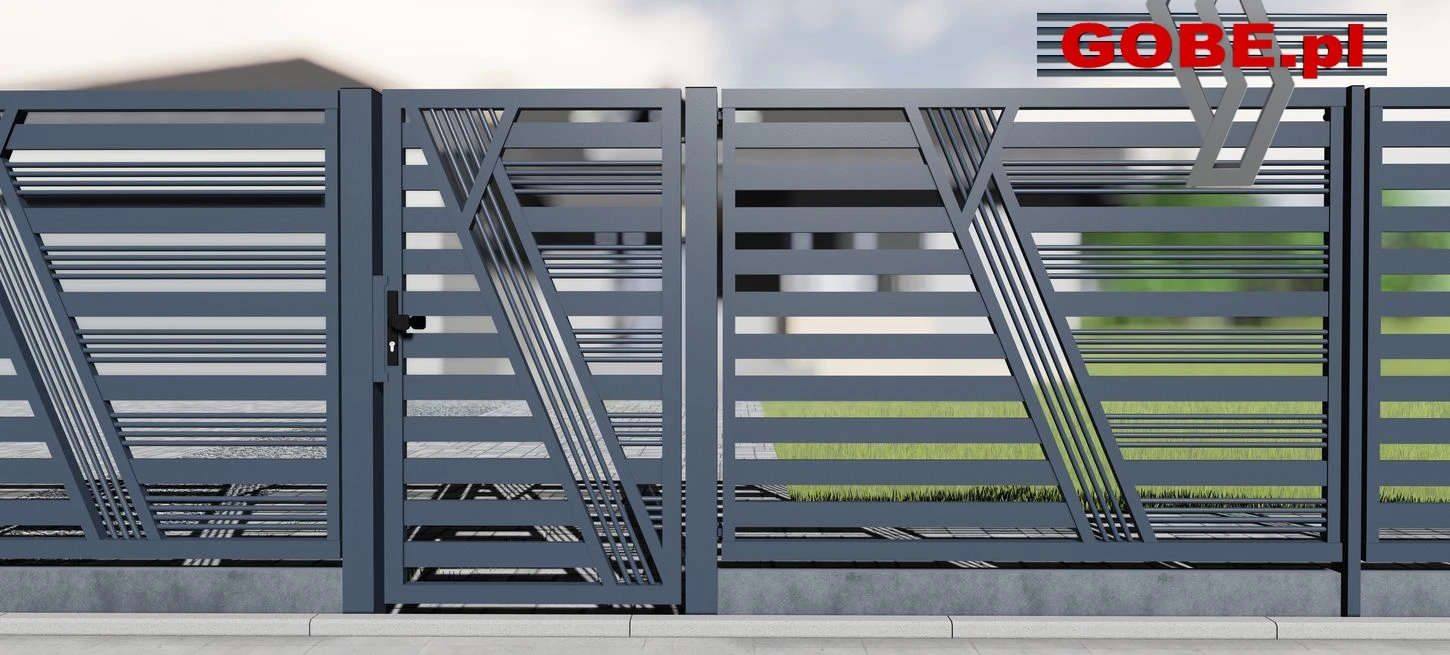

Inspiration for the construction of a metal fence in the form of a fence, one of the systems for very quick assembly of buildings, is gaining much popularity because several advantages matter, namely that the design itself presents it modestly admits it is right, but to the point, the simplicity of assembly is one thing, thus the time spent and the man-hour time generates costs and everything is clear. Cheap to assemble and a dozen or so effect meters and more possible to do in one day without unnecessary complications. You can confidently do it yourself with immediate help or for convenience order a crew, neat aesthetic effect in several moments counting with breaks.

The concept presented above is a 180 cm high fence, door handles are normally mounted 100 cm high from the pavement cube. In the case of several gate wickets on the property we use a system one key, convenience because we operate with one key at the entrance, the garbage can and for example at the entrance to the garden. As for foundation foundations or concrete slabs typically used for panel fences from the bar mesh. Any option allowed, any type can be used. In turn, concrete boards from panel systems are ok, but what we face, the quality is ambiguous, rarely colored in mass. The species are usually thicker and heavy, reaching up to 80kg in weight, which requires support and handling the right size. It is neither comfortable nor associated with the possible cutting that there is a specific length of ale when we want to preserve the high aesthetics and proportions of the fence spans, we must cut in each case.

Typical concrete slabs can be and are usually mounted by sliding them into the C-profiles attached to the posts, painted in the color of the fence, slightly expanding the posts. Another case is the typical edging curbs used when laying pavement blocks or on driveways. The advantage is dyeing in mass, qualitatively definitely great, and they occur in meter sections, it is known to operate more neatly, under metal spans, the system is placed on the prepared surface on semi-dry moist concrete, typically like periphery. Cut to the width of the panel span, work can somewhat awesome but lighter and self-contained. The effects are definitely more attractive, the operational possibilities are much more than that.

We are at the assembly of spans to the posts, as you can see in the picture above shapely independent mounting brackets, the great advantage of these mobile mounts is the possibility of independent vertical height adjustment on the post. This allows for free gradation of the fence spans when dealing with land fall along the fenced property. A proven and practical method - fence assembly technique involves drilling holes for posts, in the places provided, marked out in accordance with the attached design. Then we mount the brackets on the posts appropriately taking into account the location and height, successively attach the span fence panel to the posts. We set the assembled segment vertically by sliding posts into previously prepared holes in the ground, support from below on beams horizontally across the span to the appropriate height.

The holes for concreting are, of course, of the right depth, ensuring fence stability and resistance to freezing of the ground, so the span inserted practically stands vertically, it does not require any support. The next segments with spans are assembled as the previous ones, set up and when we have a set, correction of vertical and horizontal adjustment, the fence stands and we can cover with prepared semi-wet concrete, gently tamping controlling post position settings. The holes under the posts are filled with concrete to the appropriate height depending on the planned restoration with edging or other filling.

An alternative complement to this method of the system is to set the steel fence between the edges or curbs. We fill the space under the panels with decorative aggregate stones, of course the appropriate layer and necessary on agro nonwoven. This ensures that overgrowth of unwanted plants and grass is blocked. An appreciated advantage of this solution is the convenience of mowing the lawn, or possibly more fashionable arrangements gardens in various decorative pebbles. Imagination knows no limits.

We are next to a plastered stone fence, basically our Galaxy series fence can be mounted almost anywhere and on almost everything. Please note that we use for swing gates European standard for concealing hinges relative to the front view. Aesthetics is the advantage of opening the wings over 90 and more degrees, We also embrace the use of our appropriate mounting brackets in automation.

As you can see, the set hinges are mounted in the light of the gate entrance shifted towards the property, the entire system of dedicated hinges of our production is provided with the actuator handles used high culture of gate automation work without overloads, at the same time opening accounts can reach up to 130 degrees.

A stop stop should be installed next to each double-leaf gate with electric drive, usually located in the middle of the entrance underneath the wings, the gap should be between 4 and 5 centimeters. After closing, the gate presses against the stopwatch and stays under tension. Photocells are required and necessary, modern ones already contain LED warning lights, when laying the walls, we must remember about the preparation and introduction of control cables equally for photocells, intercom operation, a cassette with a gate electric lock and the supply of gate automation actuators.

The plaster front fences are masonry from which they can be, visually and rightly plastered, you can even level it with polystyrene. Ok, comfort and brick effect, just remember to when planning a swing gate and wicket on posts, so as not to exaggerate the thickness of the foam, it is necessary to take into account the reliability of the hinge fastening.

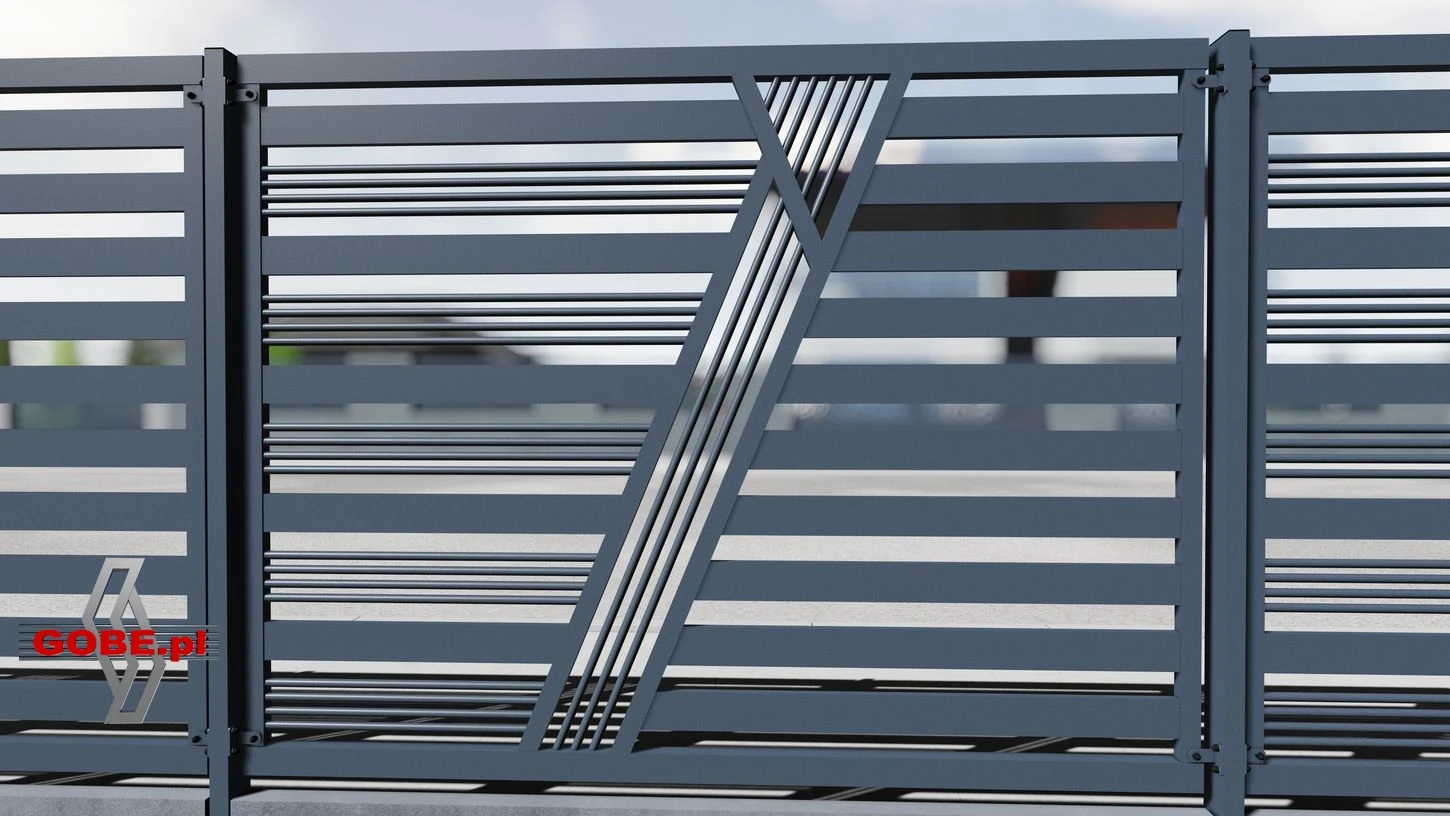

Fastening the panel span fence in dimensions 196x90, model Galaxy 374, is a typical standard hole light, the most popular version, the widths can be one more or less block. Similarly, in height, one block at a time. Visible brackets fastening the spans are not rigidly anchored in the walls, then they ensure free expansion of steel during temperature changes in winter and summer. This system protects other brick blocks from damage.